-

- About the Department

- Vision

- Mission

- Program Educational Objectives (PEOs)

- Program Outcome (POs)

- Program Specific Outcomes (PSOs)

- Faculty Of Mechanical Engineering

- Magazines

- Syllabus & Course Outline

- Laboratories

- Practices & Innovation in Teaching Learning

- Departmental Activities(Guest Lectures & Industrial Visits)

- Academic Calendar

- Project

- Research & Development

Department of Mechanical Engineering

Mechanical Engineering is one of the oldest and broadest branches of engineering. It applies the principles of physics, mathematics, and material science to design, analyze, manufacture, and maintain mechanical systems. Mechanical Engineering is the discipline that deals with mechanical systems, which can range from engines and turbines to HVAC systems, robotics, and manufacturing equipment. It provides theoretical knowledge and practical training includes industry-relevant electives and laboratory courses. Faculty and students engage in research across various domains like renewable energy, composites, robotics, AI in manufacturing, etc. MoUs with industries for internships, live projects, and placements.

Why Choose Mechanical Engineering?

Mechanical engineering is often called the “mother of all engineering branches“ because it touches almost every area of modern technology — from automobiles and aerospace to robotics, manufacturing, and energy systems. Mechanical engineers are in demand across many industries: Automotive (e.g., Tata, Mahindra, and BMW), Aerospace (e.g., ISRO, Boeing) Manufacturing & Heavy Machinery, Robotics and Automation. If you enjoy solving real-world problems, designing things, or making systems work better, mechanical engineering provides countless opportunities for creative engineering solutions.

Job Opportunities:-

UPSC, GATE, DRDO, BHEL, NTPC, GAIL, IOCL, ONGC, HPCL (via GATE), SAIL, NHPC, NPCIL, CIL, BEL, DMRC, Indian Railway, Hydro Power Plant, Thermal Power Plant, ESSAR, Mahindra, L&T, Vedanta, Ashok Leyland, CUMMINS etc.

Vision

Vision

To emerge as a center of excellence in the field of Mechanical Engineering to enhance the technical and professional skills of the students and make them competent enough to cater to the multidisciplinary needs of academia, industry and society with strong moral and ethical values.

Mission

Mission

- M1-To provide an environment for an effective teaching-learning process with the incorporation of a multidisciplinary approach to develop competent Mechanical Engineers.

- M2-To strengthen students technically & professionally in Mechanical Engineering domains using state-of-the-art technology, which leads to successful employability, higher education and entrepreneurship.

- M3- To foster an inspiring atmosphere, this induces a passion for lifelong learning with the incorporation of human values and ethics.

Program Educational Objectives (PEOs)

- PEO1:- The graduates will analyses, design and develop tools, applications and systems based on Mechanical Engineering principles to solve real life problems of industry and society.

- PEO2:- The graduates will have the capability of working individually as well as in teams with effective communication skills, leadership quality, ethical values and an instinct for lifelong learning.

- PEO3:-The graduates will have the potential for higher education, research and entrepreneurship in the field of Mechanical Engineering and related domains.

Program Outcome (POs)

Engineering knowledge

Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

Problem analysis

Identify, formulate, review research literature, and analyse complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

Design/development of solutions

Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

Conduct investigations of complex problems

Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

Modern tool usage

Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modelling to complex engineering activities with an understanding of the limitations.

The engineer and society

Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

Environment and sustainability

Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

Ethics

Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

Individual and teamwork

Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

Communication

Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

Project management and finance

Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

Life-long learning

Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

Program Specific Outcomes (PSOs)

- PSO1– The ability to analyses, design and develop systems that generate, transmit and utilize power in an efficient way.

- PSO2– The ability to be proficient in the use of automation technology required to implement mechanical engineering practices.

Faculty Of Mechanical Engineering

| Name of the faculty | Designation | Qualification | Department |

| MOHD FAIZUL HASAN | Assistant Professor & HOD | M. Tech, PhD (Pursuing) | MECHANICAL ENGINEERING |

| SHAILENDRA SINGH CHAUHAN | Professor | M. Tech, PhD | MECHANICAL ENGINEERING |

| DURGESH VERMA | Assistant Professor & Dean Academics | M. Tech, PhD (Pursuing) | MECHANICAL ENGINEERING |

| MOHAN KUMAR | Assistant Professor | M. Tech, PhD (Pursuing) | MECHANICAL ENGINEERING |

| MAHESHWAR DAYAL GUPTA | Assistant Professor | M. Tech | MECHANICAL ENGINEERING |

| JITENDRA GUPTA | Assistant Professor | M. Tech | MECHANICAL ENGINEERING |

| FAIZAN AHMAD | Assistant Professor | M. Tech | MECHANICAL ENGINEERING |

| VINAY KUMAR SHUKLA | Assistant Professor | M. Tech | MECHANICAL ENGINEERING |

| ANURAG PANDEY | Assistant Professor | M. Tech | MECHANICAL ENGINEERING |

| ASHISH DWIVEDI | Assistant Professor | M. Tech | MECHANICAL ENGINEERING |

| RAVISHANKAR VISHWAKARMA | Assistant Professor | M. Tech | MECHANICAL ENGINEERING |

| FARHAN AHMAD | Assistant Professor | M. Tech | MECHANICAL ENGINEERING |

| UMESH CHANDRA PANDEY | Assistant Professor | M. Tech | MECHANICAL ENGINEERING |

| YOGESH KUMAR SHARMA | Assistant Professor | M. Tech | MECHANICAL ENGINEERING |

| AMIT TIWARI | Assistant Professor | M. Tech | MECHANICAL ENGINEERING |

| MAHESH KUMAR | Assistant Professor | M. Tech | MECHANICAL ENGINEERING |

| VINAI KUMAR SRIVASTAVA | Assistant Professor | M. Tech | MECHANICAL ENGINEERING |

Magazines

Syllabus & Course Outline

The Bachelor’s degree in Mechanical Engineering is typically a four-year program designed to provide a solid foundation in engineering principles, mechanical systems, and design. The second year introduces core mechanical subjects like Thermodynamics, Strength of Materials, Fluid Mechanics, Material Science, and Manufacturing Processes, supported by relevant laboratory work. During the third year, students delve deeper into advanced topics such as Machine Design, Heat Transfer, Theory of Machines, Internal Combustion Engines, Control Systems, and Mechatronics. They also begin working on mini-projects and simulations using CAD/CAM and Finite Element Analysis (FEA) tools. The final year allows students to specialize through technical electives such as Robotics, Automobile Engineering, Renewable Energy, or Computational Fluid Dynamics (CFD), while also completing a major capstone project and undergoing industrial training or internship.

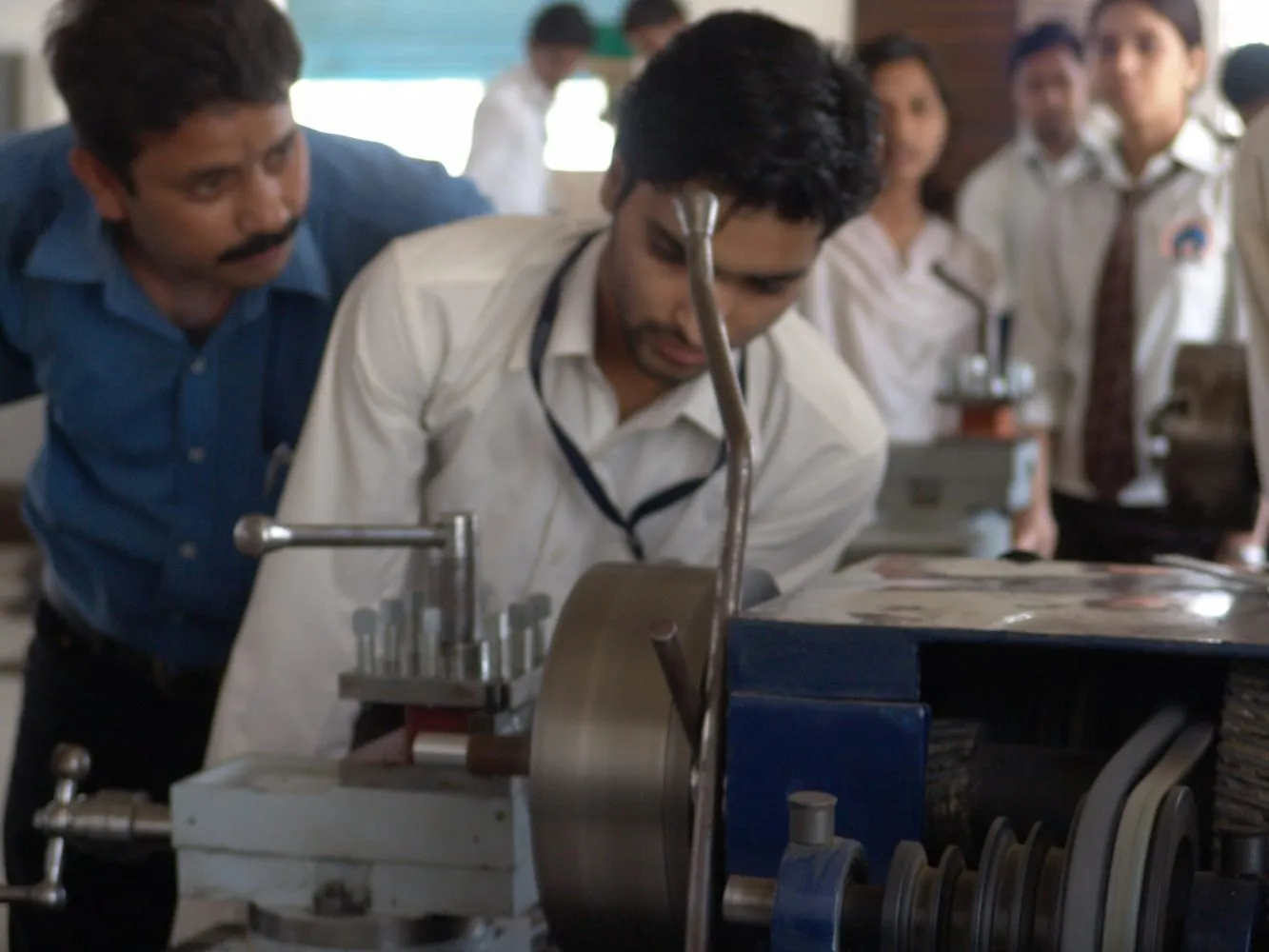

Laboratories

The department has established the following laboratories:

- Fluid Mechanics Lab

- Material Testing Lab

- Computer Aided Machine Drawing-I Lab

- Applied Thermodynamics Lab

- Manufacturing Processes Lab

- Computer Aided Machine Drawing-II Lab

- Heat Transfer Lab

- Internet of Things Lab

- Machine Design Lab

- Refrigeration & Air Conditioning Lab

- Theory of Machines Lab

- CAD/CAM Lab

- Measurement & Metrology Lab

- Project Lab

Practices & Innovation in Teaching Learning

In recent years, teaching and learning practices in Mechanical Engineering have evolved significantly to keep pace with industry demands and technological advancements. Modern pedagogy emphasizes experiential and active learning through methods like project-based learning, flipped classrooms, and simulation-based instruction.

Traditional lectures are increasingly being supplemented with digital tools, such as virtual labs, CAD/CAE software, animations, and learning management systems (LMS), to enhance conceptual clarity.

Faculty members integrate industry case studies, problem-solving sessions, and interdisciplinary projects to develop students’ critical thinking and real-world application skills. Collaborative learning environments, such as student-led workshops, design competitions (e.g., SAE BAJA, Go-Kart), and research groups, foster innovation and teamwork. Moreover, outcome-based education (OBE) frameworks ensure that learning is aligned with professional competencies and career goals.

Institutions are also leveraging AI-driven assessment tools, MOOCs, and online certifications to personalize and enrich the learning experience. These innovative practices collectively make mechanical engineering education more dynamic, industry-ready, and student-centric.

Live demonstration can be an effective tool to present material in classroom and encourage student learning. Multimedia combines basic types of media into learning environment such as text, audio, video and graphics thus providing a powerful tool for teaching.

This allows the students to pay more attention towards the concepts. It also helps the students to think and analyze the concepts in a better way. The teacher explains some topics in their regular teaching process using Software Tools /Animation / Videos to simplify their presentation. By using the system a tool, the Students understand the topics in a better way are due to animation as in compare to tradition teaching.

Each One, Teach One Learning:

Each One, Teach One Learning process is the collaboration between the faculty and students to learn and share knowledge about their community and culture. When someone learned how to read or write, it became their responsibility to teach someone else. The idea is to spread knowledge for the betterment of their community. This program will teach you how to give back to your community to learn and share knowledge.

In this connection the Department had taken an initiative the same to improve the student skill set and this methodology helps the students to improve their presentation, communication skills, and knowledge level in the concepts by self preparation and presentation. It helps the students to enrich themselves towards self learning and employability.

Students teach a topic from the subject in the presence of the teacher. The students are benefitted by Improvement in subject knowledge, self learning, & presentation skills.

Virtual Labs Learning.

A Virtual Learning Lab (VLL) in Mechanical Engineering is a digital platform designed to enhance theoretical and practical understanding through interactive, simulation-based learning.

It provides students access to virtual experiments, 3D models, animations, and real-time simulations of mechanical systems such as engines, turbines, fluid flow, and heat exchangers. These labs are especially valuable where physical lab access is limited, offering a cost-effective and safe environment to explore complex engineering concepts.

With tools like Virtual Reality (VR), Augmented Reality (AR), and Computer-Aided Engineering (CAE) software, students can visualize mechanical components, conduct virtual tests, and analyze results.

| S. No. | Name of Laboratory | Webpage Link |

|

|

Fluid Mechanics Lab | https://fm-nitk.vlabs.ac.in/ |

|

|

Material Testing Lab | https://materialsvirtuallab.org/ |

|

|

Computer Aided Machine Drawing –I Lab | https://eg-nitk.vlabs.ac.in/ |

|

|

Applied Thermodynamics Lab | https://htv-au.vlabs.ac.in/ |

|

|

Manufacturing Processes Lab | https://mp-dei.vlabs.ac.in/ |

|

|

Computer Aided Machine Drawing –II Lab | https://eg-nitk.vlabs.ac.in/ |

|

|

Heat Transfer Lab | https://ht-nitk.vlabs.ac.in/ |

|

|

Theory Of Machine Lab | https://dom-nitk.vlabs.ac.in/ |

E-Learning:

Advanced Learners are encouraged to take up various certification courses, projects based on choice and present papers in conferences/ journals. Students and faculty members are encouraged to register and utilize the NPTEL/SWAYAM program/ online certification courses of their own areas of teaching and research interests, for enhancing their teaching skills, smooth conduct of the teaching process in the regular class room teaching and for understanding the potential concepts much effectively.

The students who have not registered for any courses are supported by providing the NPTEL video lectures links of all these courses by the faculty. It helps to enrich the knowledge potentials of students and enhance their employability skills.

Employability Skill Learning:

In view of the employability of the students, department has been providing the technical and soft skills classes throughout the session for overall grooming of the students. These classes empower students with confidence, serenity, fluency etc. Also, the overall students’ qualities are enhanced.

These classes comprise of aptitude class and personality development class for two to three lectures per weeks for second, third and final year students. These classes are conducted by eminent faculties from training and placement department. During the class, regular assessment is done to observe the potential of the students. Based on the feedback, special emphasis is made to train the students to meet the requirements of the industry.

These classes are highly valuable for the students who would be taking part in group discussions and interviews and campus drives.

Project-Based Learning:

Students work on projects that engage them in solving a real-world problem or answering a complex question, over an extended time and gain knowledge & skills by working for an extended time to investigate and respond to an authentic, engaging, and complex question, problem, or challenge.

They demonstrate their knowledge and skills by developing a product or presentation. As a result, students develop deep content knowledge as well as critical thinking, creativity, and communication skills in the context of doing an authentic, meaningful project.

Project Based Learning unleashes contagious, creative energy among students and teachers. Sessions are arranged for demonstration of the working model of the projects, which is of utmost necessity for the students to have knowledge in hardware aspects.

Innovation in Laboratory Experiments:

To develop experimental skills, experience phenomena directly & Connect book knowledge to real-world applications in the students, all labs are equipped with latest equipments with standard operating procedures.

Simulations are also performed with the help of parallel and counter flow heat Exchanger for specific experiments.

Industrial Visits:

Students are exposed to industrial environment to have practical knowledge and hands-on interaction with industry executives and to bridge the gap between industry and academia. Regular industrial visit are organized for students like Gobind Industries , Cold Storage, Bakshi Ka Talab, Lucknow and summer internship in various industries.

Question Bank Management System:

The management of question banks in the field of Mechanical engineering is crucial for enhancing the efficiency of both teaching and learning processes. In the department, the management of question banks has been a manual task, with teachers responsible for typing and editing questions. Question bank structure is helpful for the various internal and external examinations as well as various competitive examinations. It includes almost all courses/ topics and difficulty level associated. A question bank for each course is prepared by concerned course instructor.

Innovative Assignment Practices:

In general practice, assignments are given to the students to improve knowledge through self-learning by referring available resources. But incorporating innovative methodology in the preparation of assignments the outcome is improved. One assignment per course outcome during the semester is assigned to improve learning ability and subject knowledge.

Mentor-Mentee Systems:

A small group of students are allocated to each faculty (mentor-mentee system). Faculty counsellor / Mentor prepare their students in individually for viva-voce & monitor their academic performance continuously. Faculty counsellor / Mentor monitor all the activities of the students.

Instructional Charts based Learning:

Many students are visual learners and understand concepts better when they are presented visually. The instructional charts are educational tools used by teachers to visually display information, an innovative tool in the teaching and learning process.

These charts present data, illustrate concepts, outline processes, or provide guidelines in a visually engaging manner. The common benefits for the students are visual learning, engagement and interest, memory aid, encourages critical thinking, an alternative way to access and understand information.

Power point presentation based Learning:

Using, power point presentation, an innovative tool, the faculty can create & engaging visual presentations, allowing faculty and students to communicate ideas, information, and concepts effectively through slides that can include text, images, videos, and animation, etc.

Video Lectures based Learning:

The department extensively practice video lectures based learning in using video as the primary medium for delivering educational content, offering a multisensory learning experience that combines audio, visuals, and text. The benefits for students are that videos can capture and maintain attention better than traditional text-based materials, leading to increased engagement and better knowledge retention, improved comprehension, and accessibility and convenience.

Seminars:

The faculty also utilizes the seminar-based teaching, a form of innovative learning, for students discussing pre-assigned questions or issues in small groups, guided by the teacher.

It encourages active participation, collaboration, and critical thinking, moving beyond traditional lecture-based learning.

Expert Lectures:

In order to offer our students latest insights into the emerging technologies and advancements, expert lecture series are organized to help our students gain strong foothold in the field of Mechanical engineering and help them stand out among the rest.

Instead of solely relying on traditional lectures, instructors can utilize expert lectures to provide foundational knowledge and then engage students in activities like research, application, and problem-solving. This approach fosters deeper understanding and encourages active learning.

Guest Lectures and Industrial Visit

| Guest Lectures/ Workshop /Industrial Visit | Date | Resource Person with designation / Organization |

| Industrial visit ( ME-3rd Year) | 25/03/2023 | Cold Storage, Bakshi Ka Talab, Lucknow |

| Guest Lecture on Industry 4.0 | 10/04/2023 | Dr. Vineet Dubey

Assistant Professor Mechanical Department |

| Guest Lecture on Future Of Mobility | 20/04/2024 | Er. Akash Pandey (Senior Manager, Tata Motor Limited, Lucknow) |

| Workshop on Drone Technology | 18/04/2023 | Mr. Mohd Faizul Hasan

Assistant Professor RRIMT, Lucknow |

| Workshop on AutoCAD | 05/05/2023 | Er. Lalit Mohan Bhatt

(Trainee) |

| Guest Lecture on Transforming Industries: CFD and Molecular Modeling for Entrepreneurial mindset | 25/11/2023 | Dr. Anshul Yadav

( Scientist) CSIR, Gujarat |

| Guest Lecture on The Startup Journey: From Idea to Execution | 23/12/2024 | Dr. Ujjwal Chugh

Entrepreneur, Author & Digital Visionary Skill & life engineering mentor |

| Solar Expo visit | 07/03/20025 | Indira Gandhi Pratishthan, Lucknow |

Academic Calendar

Project

| Name of Student | List of Project | Session | |||||

|

|

2023-24 | |||||

|

|

2023-24 | |||||

|

|

2023-24 | |||||

|

|

2023-24 | |||||

|

|

2023-24 | |||||

|

|

2023-24 | |||||

|

|

2023-24 | |||||

|

|

2023-24 |

Research & Development

| Name of Faculty | List of Publications with Title |

| Mr.Mohd Faizul Hasan | Investigations on sensing capability of waste sugarcane bagasse for arsenic ions from aqueous medium.

International Conference on Advances in Smart Materials, Chemical & Biochemical Engineering Volume-102, Issue- 09-JUNE-2023, DOI : https://www.sciencedirect.com/science/article/abs/pii/S221478532303170X |

| Fabrication and evaluation of physical and mechanical properties of juteand coconut coir reinforced polymer matrix composite.

International Conference on Advances in Smart Materials, Chemical & Biochemical Engineering Volume-38, Issue-31-july 2020 |

|

| Effect of TiC and graphite reinforcement on hardness and wear behaviour of copper alloy B-RG10 composites fabricated through powder metallurgy

JMST Advance journal ISSN: 2524-7913, Volume 4, Issue 02, 2022 |

|

| Mr. Durgesh Verma | Investigations on sensing capability of waste sugarcane bagasse for arsenic ions from aqueous medium.

International Conference on Advances in Smart Materials, Chemical & Biochemical Engineering Volume-102, Issue- 09-JUNE-2023, DOI : https://www.sciencedirect.com/science/article/abs/pii/S221478532303170X |

| Mr.Maheshwar Dayal Gupta | Investigations on sensing capability of waste sugarcane bagasse for arsenic ions from aqueous medium.

International Conference on Advances in Smart Materials, Chemical & Biochemical Engineering Volume-102, Issue- 09-JUNE-2023, DOI : https://www.sciencedirect.com/science/article/abs/pii/S221478532303170X |

| Mr. Ashish Dwivedi | Analysis of Most Effective Critical Success Factor that Help Industry to Implement Green Supply Chain Management.

International Journal of Emerging Technology and Advance Engineering ISSN-2250-2459(O) , volume 6, Issue 5,may,2016 |

- Address

NH-24, Bakshi Ka Talab, Sitapur Road, Lucknow-226201 (UP) India - Phone

8756008853, 9161888853, 18001020833 (Toll Free) - Email

admissions@rrgi.in - rrimtedu@gmail.com